Completed parts - 2

These are the second set of printed parts that (mostly) work.

Now we have all parts printed--no Xtend-a-Slide parts at all. All parts printed with TransiDupe Version .9.019. They are mostly printed with black filament. The oldest part is printed with gold filament.

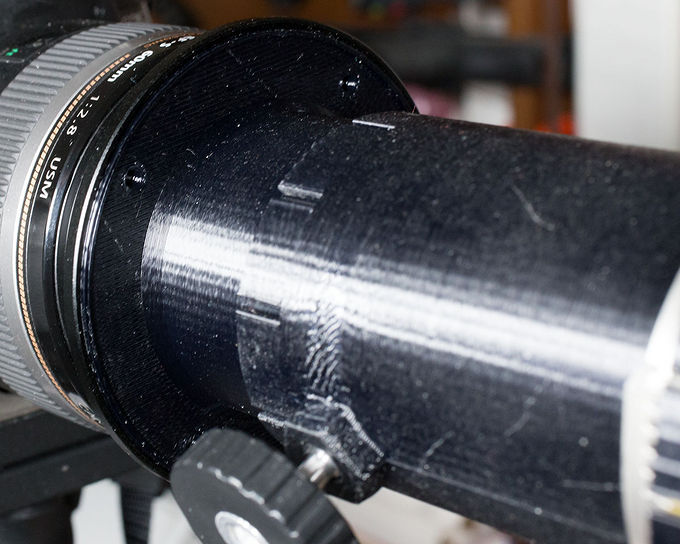

I moved up to a 52-77mm step-up ring. The threads on the back of the rear tube work much better at 77mm than they do at 67mm or 58mm. I also added an alternate plan B, which is adding four holes in the rear plate. (See third picture, below.) If the threads on the rear plate turn out to not hold, then the step-ring can be drilled where the holes and secured with small nuts, bolts, washers. I put the holes in the plate because they get reinforced that way. The slicer draws several layers of circles around each hole.

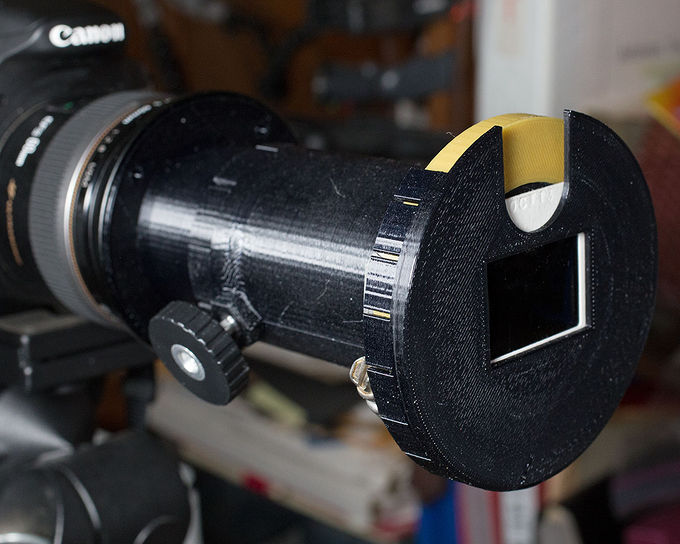

3D printed front tube.

Note the thumb screw. It it a standard 1/4" - 20 tripod screw that screws into a Home Depot 1/4" - 20 nut that is behind the hexagonal shaped blob. The slits on the front tube were too short for a hose clamp. But the thumb screw works quite nicely, so the hose clamp isn't needed. The slits will go away the next time around.

(I have nylon thumb screws on order . For now, I'm being real careful with the metal tripod screw.)

Also, the front plate (that is printed in gold filament) is really supposed to be printed as part of the front tube. I temporarily made them be two different parts, so I could work on each part individually. Once everything is working, then I'll merge the front plate with the front tube (so that hose clamp won't be needed.)

Front view

The slide carrier is obsolete as I write. I am printing another version that has a longer slitted section. I decided that a hose clamp will work there--it is good to really lock things down. (A hose clamp works on the version in this picture, but the slitted portion is too short.)

Attached to three sections of an Xtend-a-Slide tube

Attempt to show the holes on the rear plate. You can see one of them if you squint hard enough.

I haven't figured out an elegant to fix the slide being low because of drooping. So I'm punting by raising the slide carrier by the amount of droop. This is trial-and-errory, but it works. For now.

Contact me about questions or suggestions

Questions? Write to transidupe@frogymandias.org