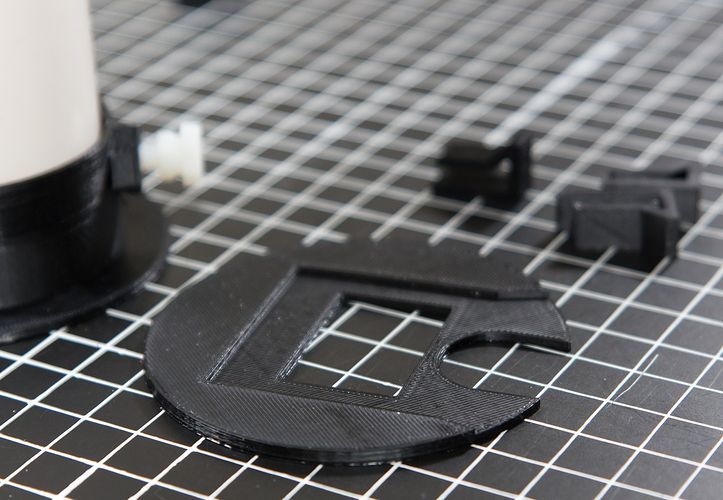

Completed parts - 3

This is a redesign that uses 2 inch PVC (plumbing) pipe for the long tube. Because printing the long tubes takes hours (but it only takes a few minutes to hacksaw a length of PVC pipe.) I also redesigned the front carrier to eliminate the slotted rim (which removed another hour from print time.)

The top is the step-up ring that screws into the lens. I found that I needed to add clips because the 3D printed threads on the rear plate sometimes weren't strong enough to screw securely into the step-up ring. I got the clips from Home Depot. Because 2" PVC pipe is a bit larger in diameter than the previous prototype, I had to use a 86mm step-up ring

The slide carrier is now held on with clips.

Detail of slide carrier.

The Home Depot clips didn't work on the slide carrier, so I made 3D printed clips. The clips I 3D printed were difficult to put on so I used 3/4" spring clamps from Home Depot. For now.

First generation 3D clips. They held, but were difficult to put on. (I later added handles to them, but haven't updated the pictures yet.)

Cutting PVC tube is easy. I use a $15 miter box/saw combination I got from Home Depot.

I wood screwed the miter box onto a spare cart I had in my basement.

Note the pegs for holding the pipe in place. I originally tried a cheaper miter box that didn't have the pegs and decided that splurging for the $15 version was a good idea. The pegs help a lot.

Note that there is no code at this point. Because the code has so many difference configurations and combinations, well, it needs reorganizing. Later...

Contact me about questions or suggestions

Questions? Write to transidupe@frogymandias.org